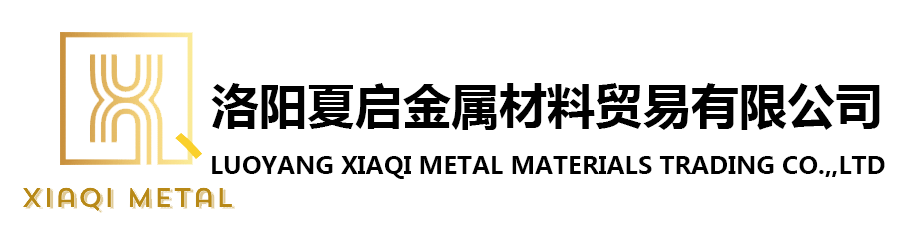

Brass strip billet

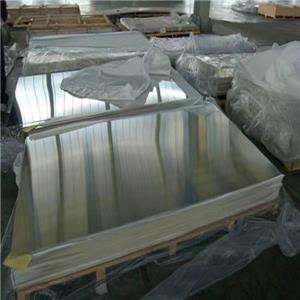

Copper ingot hot rolling is a process for manufacturing copper products, mainly used to produce various copper and copper alloy ingots, copper pipes, copper plates, copper strips, copper rods, etc.

Pour the copper raw material into the smelting furnace to melt, pour it into the mold by pouring, and obtain the copper ingot after cooling, put the copper ingot into the heating furnace to heat, so that the temperature reaches the temperature suitable for hot rolling. The heated copper ingot is hot-rolled through a rolling mill to make it into a copper plate, copper strip, etc. of a certain shape and size.

The hot-rolled copper products are subjected to various processes, such as cleaning and milling, winding, cold rolling, etc.; the purpose of cleaning and milling is to remove the scale on the surface to make the surface bright.

During the hot-rolling process of copper ingots, the uniformity of grain size can be ensured, thereby improving the quality of copper products. In the process of hot rolling billet opening, the key to eliminating pores is to control the quality and heating temperature of copper ingots. Appropriate copper alloy composition and accurate melting temperature can reduce the generation of pores. In addition, in the hot rolling process, it should be well controlled Heating and rolling process parameters to ensure that the gas and temperature of copper ingots can be fully removed, so as to obtain high-quality copper plates, copper strips and other products.

Hot rolling of copper ingots can produce copper products on a large scale and quickly, with high production efficiency. Compared with other manufacturing methods, the cost of copper ingot hot-rolling blanking process is low, and the energy utilization rate is high, and the application range is wide, etc.